TTK Project Case Study: TTK in DAMAC mall, UAE

TTK WATER LEAK DETECTION SYSTEM IN DAMAC MALL, UAE

View the case study in PDF format.

About The Project

DAMAC Properties, established in 1982, is one of the largest real estate developers in the UAE and the broader region, with over 100 high-rise buildings, including iconic residential, commercial, and leisure properties in Dubai alone.

Project Requirements

TTK ME started collaborating with DAMAC two years ago when the company faced serious leak issues and sought a reliable leak detection solution to protect their technical areas.

The initial installation of this project was a Proof of Concept (POC), and following this installation, TTK’s solution has now been approved for expansion across the client’s properties.

Monitored Areas

The project focuses on protecting the lift pits and technical areas.

TTK’s Solution

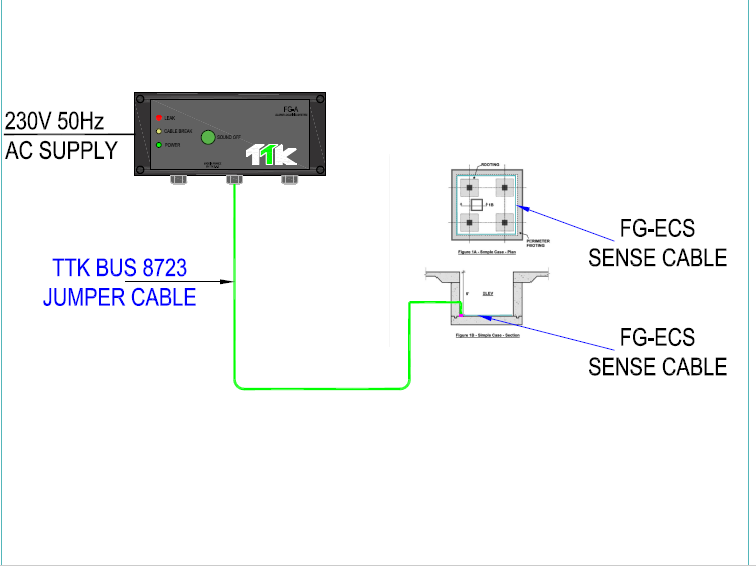

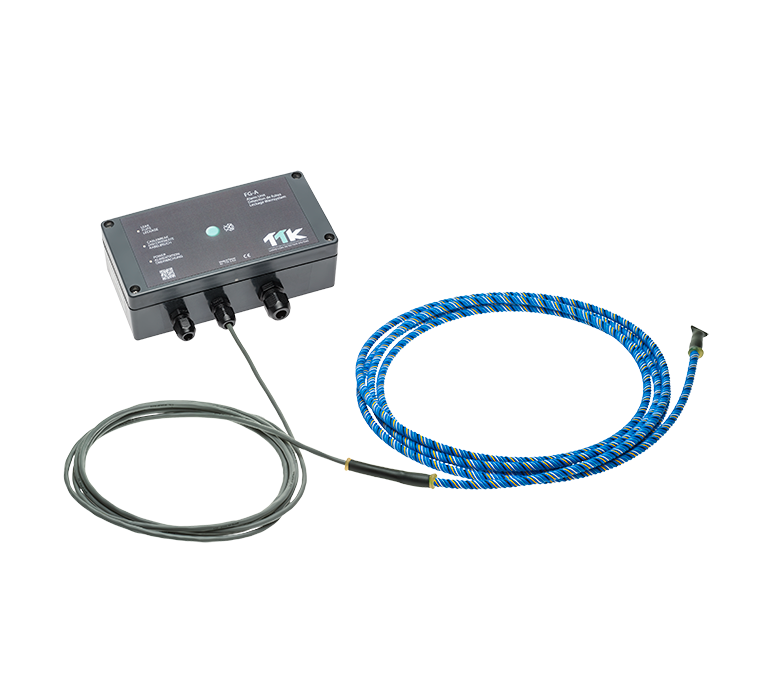

After conducting a site visit and engineering study, TTK ME recommended a stand-alone water leak detection kit. The solution includes a custom-built FG-A panel paired with a 7m FG-ECS water sensing cable, installed inside the trenches.

The FG-A panel is compact, easy to install, and wall-mounted. It offers both visual and audible indicators on the front panel, making it easy to identify the type of fault (leak or cable break). Two zero-volt contact relays provide multiple signaling options and allow for centralized monitoring. The panel’s sensitivity can be adjusted using a potentiometer on the PCB, allowing customization based on the surrounding environment.

Additionally, for this project, the client requested that the leak detection system integrate seamlessly with the building’s central control system (BMS). To meet this requirement, TTK proposed a custom-built panel with a Modbus option, enabling communication through the Modbus protocol.

In the event of a leak anywhere along the 7m sensing cable, the FG-A panel emits an audible alert and simultaneously sends a report to the BMS, which can be monitored in the central control room. This enables operators to quickly identify and locate the issue, ensuring rapid response before the leak spreads, minimizing the risk of equipment failure, and reducing downtime.